Buzzsaw

TIMELINE

SEPTEMBER 2024 - MAY 2025

WEIGHT CLASS

3-LB COMBAT ROBOT

AWARDS

2ND-PLACE, MOST INNOVATIVE

SUMMARY

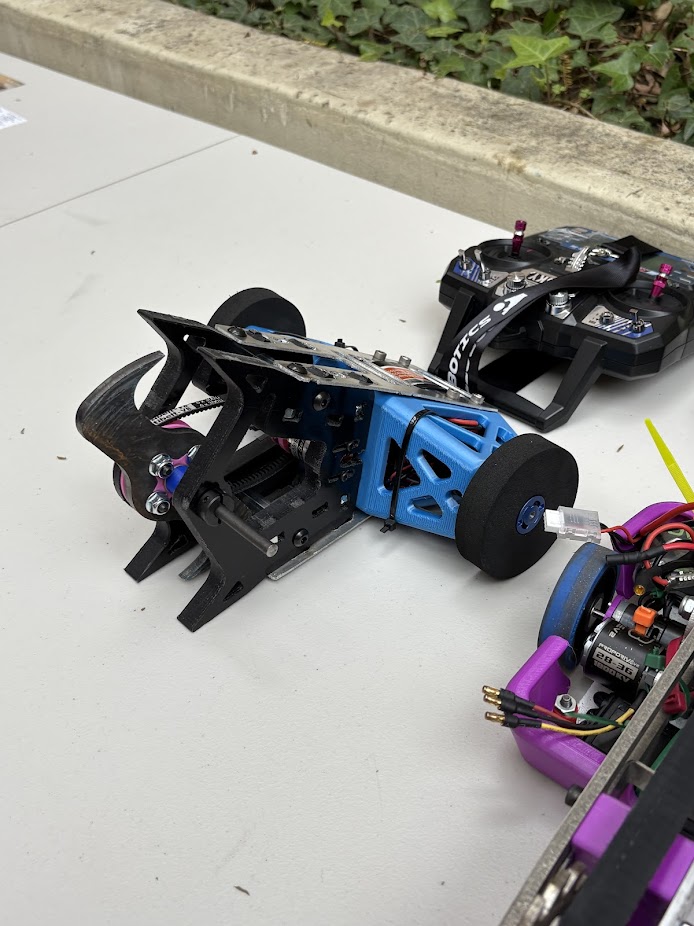

As technical lead for UCLA Combat Robotics, I was responsible for teaching 40+ students to design, build, and wire three pound combat robots from start to finish.

I participated myself, ultimately placing 2nd place with Buzzsaw in our competition, Mechanical Mayhem! I designed, wired, built, and competed the robot by myself.

I planned on being able to articulate the arm of the weapon, but ultimately settled on leaving the arm as stationary.

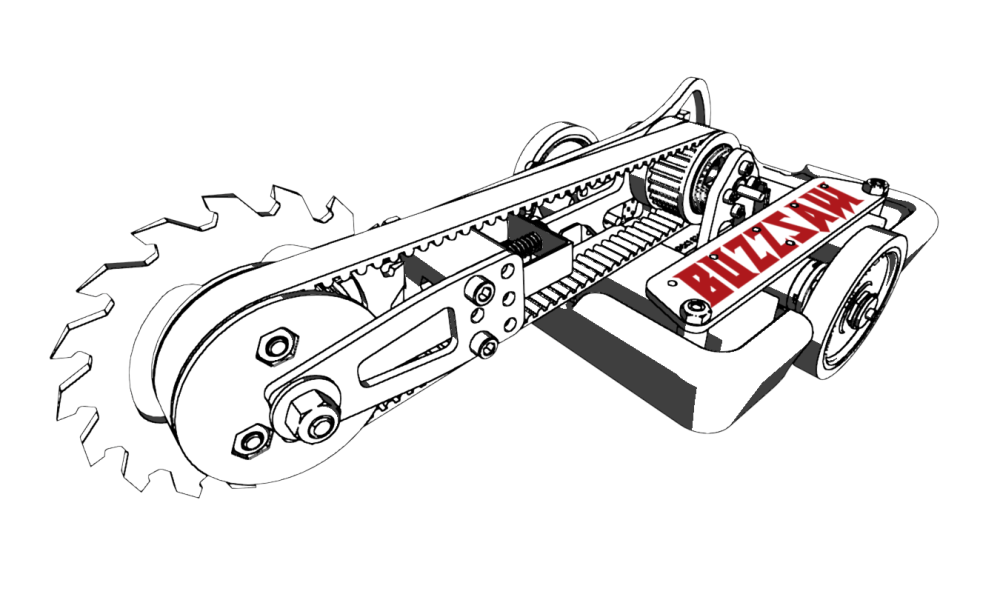

It all started in the 2D world of Solidworks, as always.

I set basic, yet important dimensions that can be changed later on to give myself a place to start.

I actually changed the pulley sizes from this, based on calculations using physics equations. The main equation used is KE=1/2Iw^2. This allowed me to estimate the energy stored in the saw based on the motors speed, the pulley ratio, and its moment of inertia. I aimed for 250J of rotational energy.

I often design entire assemblies in one part, and then split the parts once I’m finished. This allows for easy parametric design and the ability to directly reference geometry of other parts. This design method is called the multibody design method.

This is the entire robot, with all the bodies in one part! It really speeds up the design process, because I don’t even have to mate the parts together. I just make them off of each other.

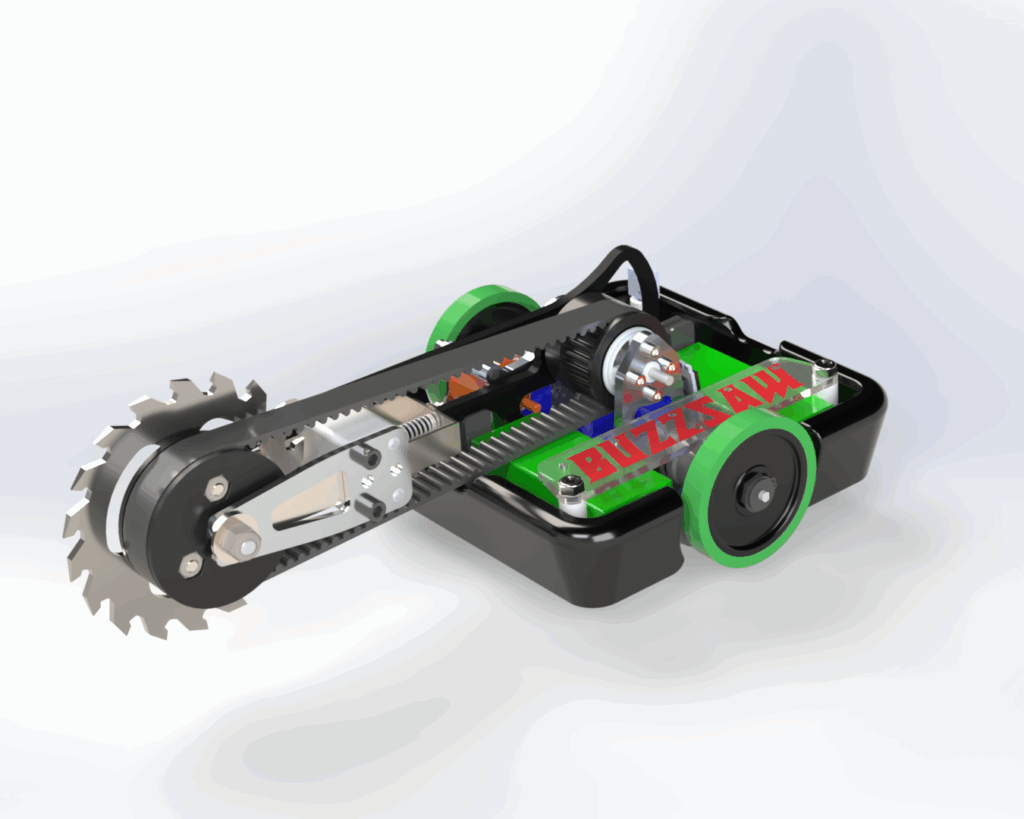

Final Render showing all the parts in photorealistic detail!

Done in Solidworks Visualize 2024

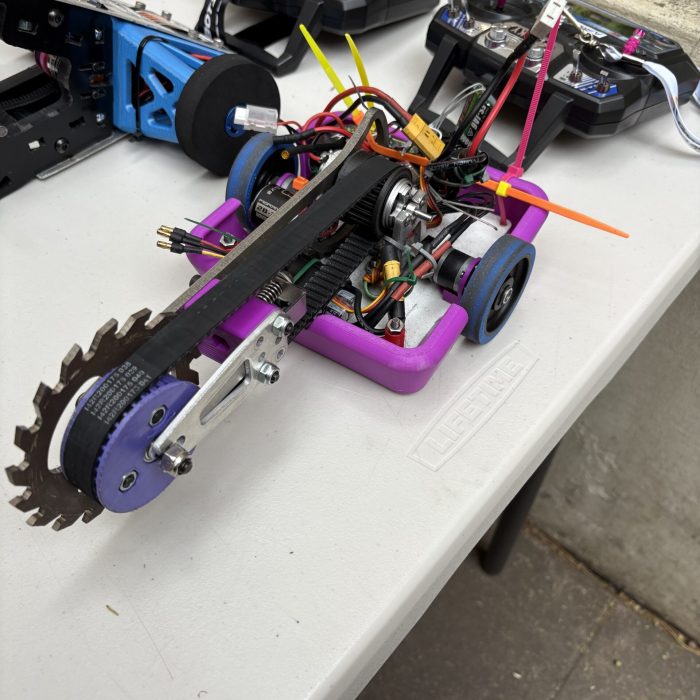

I 3D-printed parts such as my weapon’s timing pulley and arm’s crush block.

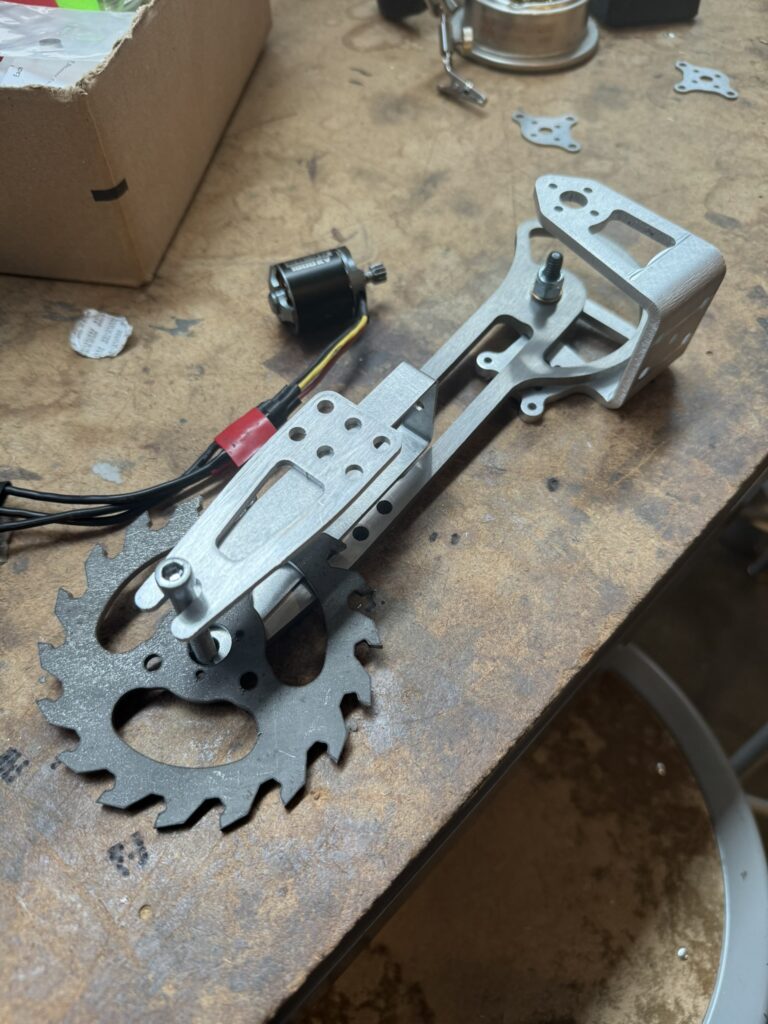

Soon enough, my ordered parts started arriving. My favorite part is my central aluminum weapon system, which is a bent plate. I ordered it from a company called Fabworks, which specializes in lasercutting & bending parts.

I also ordered many parts from SendCutSend, which waterjets parts from 2D drawings. The longest part, the arm, is made from titanium! Thankfully they gave us a 20% discount!

A key feature is the thin bent steel belt tensioner. It screws through the arm crush block, pushes against the shoulder bolt, and by using a spring, optimal tension can be adjusted.